Pelltech pellet burner is produced in Estonia

Fully automatic pellet burner PV 30b, Pelltech 14-30 kW. Pellet burner with automatic cleaning. Unique electric ignition, automatic power selection, control panel with menus in Estonian.

The PV 30b pellet burner is a further development of the PV 30a series burner model, equipped with an automatic combustion chamber cleaning system. By connecting the burner to a compressor, it blows the ash generated in the combustion chamber into the boiler, and the weekly burner cleaning requirement is extended up to one month!

The PV 30b pellet burner can be installed on pellet, oil, biomass or universal boilers with a 90 mm flange.

The unique electric ignition and automatic power selection make the pellet burner easy to use all year round. No pilot flame is used in the combustion process.

The burner is protected against back-burning by a safety thermostat, a hose made of fusible material, a temperature sensor and a support battery.

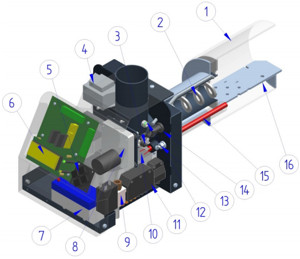

Components of pellet burner PV 30 b

1. Combustion chamber – the place where pellets are burnt. The combustion chamber tube is made of heat-resistant 253MA steel.

2. Siseteo coil – transports the pellets into the combustion chamber. The amount of pellets that can be dosed at one time depends on the burner capacity. The coil oscillates noticeably at the motor end to prolong the life of the motor. Do not over tighten the coil attachment pin.

3. Safety thermostat – turns off the burner mains supply and external supply if the internal supply temperature rises above the permissible temperature. This is a safety precaution against backfiring.

4. Power transformer – 230/12V transformer for powering the processor and the internal heater motor.

5. User interface buttons – allow you to navigate the burner menu and set burner parameters.

6. User interface screen – 2-line screen for navigating through menus and setting parameters.

7. Battery – Allows to discharge the internal combustion heater and burn the fuel in the combustion chamber to the end if the mains power is lost. This is a safety precaution against back-burning and lasts approximately 30 minutes.

8. Inseteo motor – moves the inseteo coil to deliver pellets to the combustion chamber. The spiral attachment to the motor is made with a noticeable slack. This helps to prolong the life of the motor.

9. Pneumo valve – controls the flow of compressed air in a self-cleaning cycle.

10. Fan – blows combustion air into the combustion chamber according to the burner’s current capacity.

11. Connectors – for connecting the mains supply, the boiler thermostat and the external supply.

12. “Fuel level sensor” means an optical sensor consisting of a transmitter and a receiver, the signal from which triggers an external device.

13. Fixing nut – M6 nut that fixes the burner body to the combustion chamber.

14. Flame detector – Optical sensor for detecting the flame in a combustion chamber.

15. Spark plug – an electric heater that heats the air to ignite the pellets.

16. Combustion grate – a heat-resistant 4 mm 253MA metal combustion chamber base with air vents on which the pellets burn.

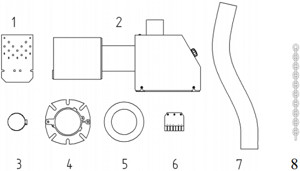

The pellet burner PV 30 b is supplied in the following configuration:

1. Combustion grate

2. Pellet burner

3. Hose clamps (2 pcs)

4. Fixing flange

5. Ceramic gasket

6. 7-pole boiler plug

7. Hose

8. External fixing chain

Working principle of the pellet burner PV 30 b

The PV30b pellet burners are installed on the boiler for the combustion of wood pellets. The pellets are transported from the pellet hopper to the burner by an external pellet conveyor. The burner control panel contains a microprocessor that tests the main

safety components, regulates and monitors the combustion process, starting and stopping it according to the boiler temperature. An electric air heater or igniter ignites the pellets. Ignition of the fuel is fast and

smoke-free.

The burner starts burning the fuel when the boiler has cooled down and the boiler thermostat switches on. The firing continues until the boiler reaches the pre-set (shut-off) temperature. After that, the burner stops the heating process and goes into standby mode.

The burner control system ensures the safe shutdown of the burner in the event of a power failure. After a power failure, the burner safely stops the combustion process and switches off. The burner will shut down in case of any hazard risk.

Self-cleaning

The pneumatic self-cleaning system consists of a compressor, a pressure hose, a pneumatic valve and a metal tube installed in the burner’s inner tube.

The pellet burner PV 30b performs self-cleaning:

– always after testing,

– after PAR48 set time (in minutes) for intermittent operation,

– after PAR48 set double delta (in minutes) for continuous operation.

Self-cleaning is carried out by blowing compressed air into the combustion chamber of the pellet burner, which cleans it of accumulated ash and non-combustible residues. The ash is blown from the pellet burner into the boiler ash box. The length of the blowing time is adjustable by PAR49 (in seconds). The pellet burner maintenance interval depends on the quality of the pellets and the heating intensity.

Thanks to the self-cleaning system, the pellet burner cleaning time is extended up to one month.

![[EZB-09RD6-I-EZ-09RD6H-O] Midea Solstice EZ R32 Kit cell-humidistat-heat pump-heating unit](https://calidum.ee/wp-content/uploads/2024/05/EZB-09RD6-I-EZ-09RD6H-O-Midea-Solstice-EZ-R32-Komplekt-rakve-virumaa-kliima-soojuspump-kute-1024x1024.jpg)