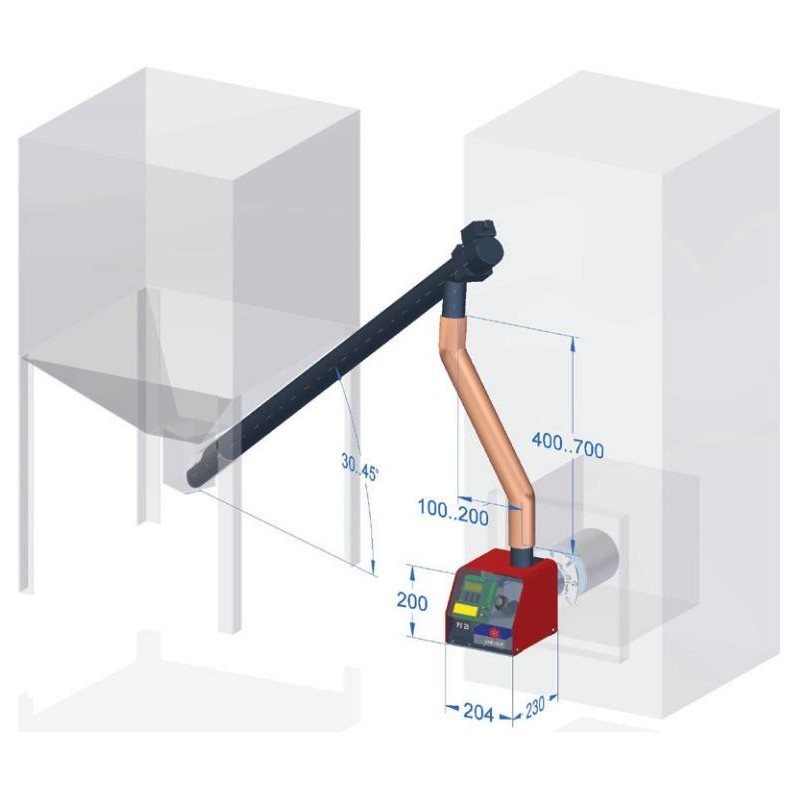

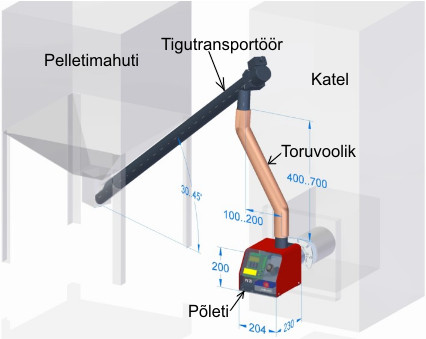

Pellet burner feed chute

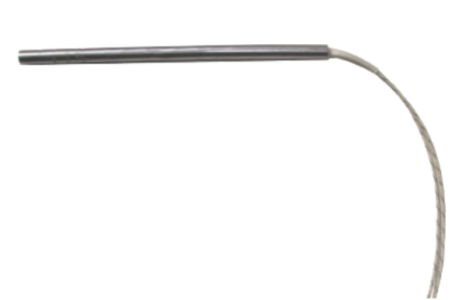

The pellet conveyor (external pellet conveyor) transports the pellets from the pellet hopper to the pellet burner. The pellet burner controls the work of the auger conveyor. The pellet conveyor is connected to the burner (e.g. Pelltech PV20/30) with a special 60mm hose. The hose is made of fusible polyurethane material. The hose is a safety element as it melts on re-ignition.

The pig conveyor can be attached to the pellet container or to the ceiling, depending on the possibilities.

As the hose is a safety element, it must be installed as follows:

– Hang the hose reel on the ceiling or burner so that the requirements below are met.

– Install the hose between the reel and the burner. Fasten the hose at both ends with a metal clamp.

– Connect the motor cable of the auger conveyor to the burner. Make sure the plug is securely connected to the socket.

Please note:

– The vertical distance between the outlet of the auger conveyor and the burner must be 400-700 mm.

– The horizontal distance between the outlet of the auger conveyor and the burner must be 100-200 mm. This will ensure that in the event of a backfire the flame will melt the hose and the fire will not bypass the snail conveyor into the container.

– The angle of inclination of the snail conveyor shall not exceed 45° to the ground. Otherwise the auger conveyor will not be able to transport sufficient pellets.

– The angle of descent of the hose must be between 50° and 85° to allow the pellets to fall freely into the burner.