Pelltech Everclean 100 is produced in Estonia

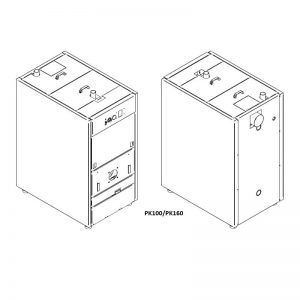

The Everclean PK100 Pelltech pellet boiler is a high-efficiency, two-coil boiler for burning wood pellets. The pellet boiler has a self-cleaning system.

The pellet boiler self-cleaning system allows easy and periodic cleaning of the heat exchanger tubes. The pellet boiler controller controls the frequency of the cleaning cycles according to pre-set parameters. The pellet boiler self-cleaning system conveys the accumulated ash to a large ash box, which is easy to remove and empty.

The pellet boiler has two doors allowing access to the boiler: the burner door and the ash box door. The ash box can be taken out through the ash box door.

The flue gas inlet, which regulates the draft of the pellet boiler, is integrated in the flue gas outlet from the boiler. The speed of the smoke extractor motor is controlled by a pellet burner controller according to the low pressure in the burner combustion chamber or according to the selected power level. The position of the flue pipe can be easily changed from horizontal to vertical. The pellet burner has two thermostats – a safety thermostat and an operating thermostat. The boiler has temperature and pressure gauges. All temperature sensors are mounted in the ½ “thermostat tube. The pressure gauge sensor is installed in a ¾” pipe.

![[EZB-09RD6-I-EZ-09RD6H-O] Midea Solstice EZ R32 Kit cell-humidistat-heat pump-heating unit](https://calidum.ee/wp-content/uploads/2024/05/EZB-09RD6-I-EZ-09RD6H-O-Midea-Solstice-EZ-R32-Komplekt-rakve-virumaa-kliima-soojuspump-kute-1024x1024.jpg)